· Available in 3015 and 4020 designs.

· Nozzle change, and nozzle alignment are automated. This enables increased machine autonomy and necessary operator intervention is reduced to a minimum.

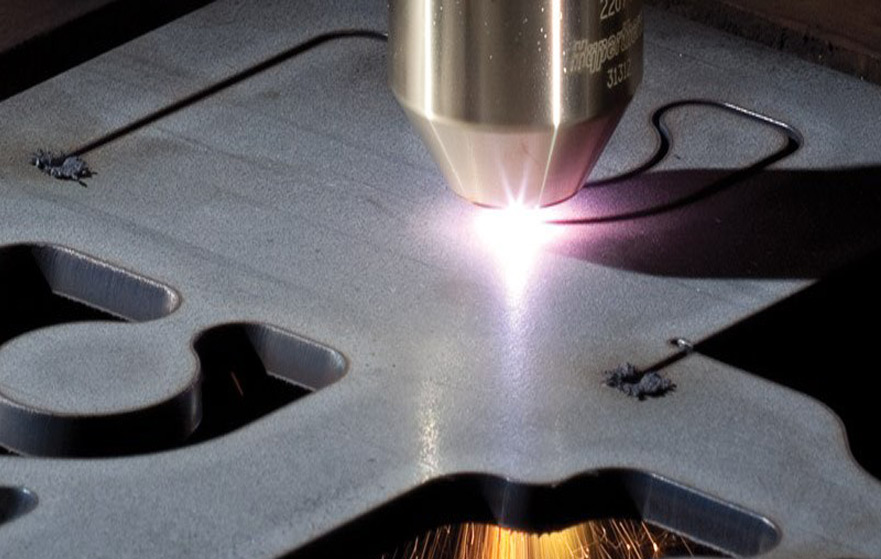

· The newest cutting and piercing technology delivers fast job processing and maximum parts production as well as first-class quality across the entire range of sheet thickness.

· The shortest cutting time per part thanks to efficient combination of laser-plasma-supported high-speed cutting and high machine dynamics.

· The optional machine encapsulation reduces smoke emissions and noise to a minimum.

· Low operating costs thanks to wear-free semiconductor excitation and wear-free magnetic bearing compressors.

Use of the latest cutting technologies such as RPP and high-speed cutting guarantee the highest level of productivity.

· High cutting speeds thanks to compressed air cutting up to a material thickness of 0.120 in.

· 10% higher output power with at least 10% lower power consumption.

· High dynamics without expensive and complex additional axis.